Solutions

Product design

Accelerate time to market by utilizing reverse engineering to combine off-the-shelf parts and assemblies with custom-designed parts.

Prototyping

Digitize hand-built prototypes commonly made using foam, cardboard, or modeling clay to accelerate the creation of production-ready designs.

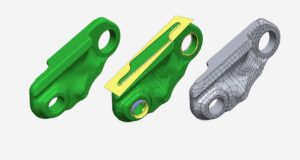

Redesign and customization

Scan an existing part or an entire product to create a 3D reference for a brand new or customized product.

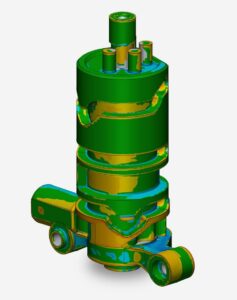

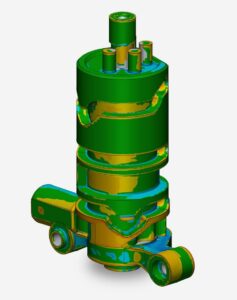

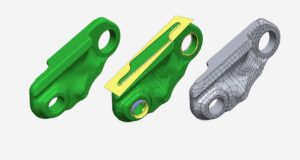

Additive manufacturing

Utilize initial design ideas for the parts that have been topologically optimized, and generate feature-based results available for further edit and use in CAD.

Optimization of supply chain

Create a digital database for key parts with high wear and tear, or parts that fail frequently, to shorten turnaround time and unify your expertise and manufacturing capabilities.

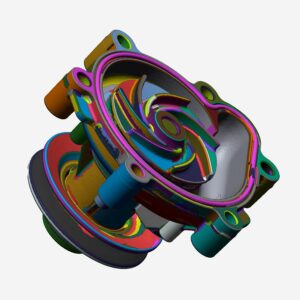

Casting

Quickly create production-ready 3D models for broken castings, and reproduce key components with 3D scanning and scan-based design.

Remanufacturing and maintenance

Use 3D scan data to manufacture replacement components and spares for expensive heavy equipment in the event of an emergency, and to keep them functioning efficiently.

Sheet metal stamping

3D scan stamping dies that have been modified after manufacturing to update the original CAD drawings and represent as-built conditions.